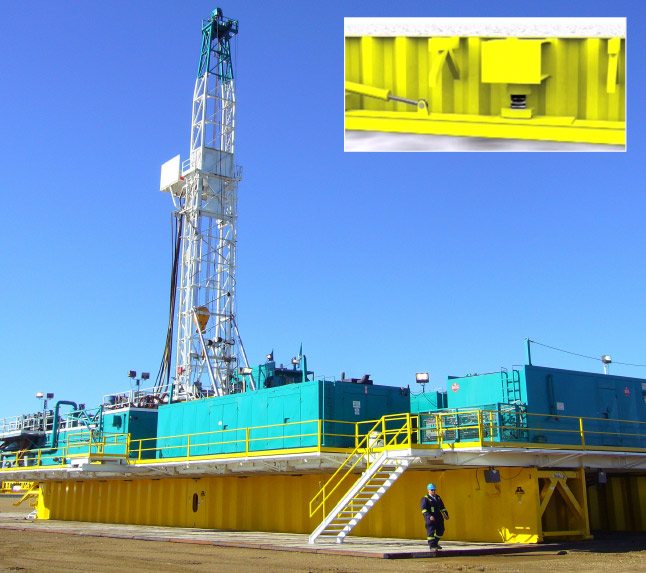

Bigfoot Rig Walking System

Scalable-Capacity Drilling Rig & Substructure Moving System

The Bigfoot Rig Walking System is a patented, scalable-capacity drilling rig and substructure moving system. The Bigfoot’s intelligent design incorporates the use of rollers coupled with lift cylinders and a low-pressure hydraulic system. Combined, these systems work to lift the main walking beams that support the rig’s weight. Smaller plank beams run the full length of the walking beams to provide support to the rollers.

The horizontal movement that transports the rig occurs as a result of travel cylinders connected between the main and plank beams. The lift and travel cylinders then actuate in sequence to transport the rig at a safely controlled pace.

- Easily disassembled into truckable loads for transport to the worksite.

- The Bigfoot system is easily assembled by a small crew with a crane and basic equipment.

- Wireless pendant control provides the operator with free movement and improved visibility during rig moves.

- Optional hardwired pendant control with easily-adjustable steering linkages.

- Scalable capacity and custom design mean our systems can meet the needs of any job.

Capacity: Scalable capacity from 2,000,000 lbs. to well over 12,000,000 lbs.

Cycle Time: Approximately 4 feet per minute allows for precise positioning of the entire structure within 1/4".

Safety Features: The hydraulic system is a safe, low pressure system, that ensures smooth operation. The main lift cylinder hydraulic circuit features counterbalance valves that hold the cylinders in position in the event of a hose rupture or breakage. Emergency stops are mounted on both the power unit and handheld controls that will shut down the motor and valves of the hydraulic power unit.

Walking Cycle: Lift cylinders raise the rig, then travel cylinders push the substructure along the center plank on rollers. The lift cylinders then lower the load and the travel cylinders retract for another pushing cycle. Steering adjustments are made by hydraulic cylinders while the load is off the rollers.

Hydraulic Power Unit: A self-contained hydraulic power unit is included, requiring only a 3-phase power connection for operation. The power unit can be located on top of the unit itself, near the rig modules, or within the rig structure.

Paint: We prepare surfaces for the paint process with a thorough cleaning and apply a three-part epoxy paint system in the customer’s choice of color.

Easy to Transport & Assemble On-Site

To make the transport of our custom rig walking system convenient, we’ve designed the Bigfoot so that you can disassemble the entire system into loads transportable by truck. Each of the Bigfoot’s beams features an integrated tail rolling hitch to make them easier to move using most standard oilfield trucks. The Bigfoot system offers the flexibility to operate regardless of how poorly setup a location’s condition. When needed, the Bigfoot can even vertically lift the entire rig for leveling.

When arriving on-site, the Bigfoot can be easily assembled by even a small crew using a crane and other basic equipment. Columbia Industries will provide a detailed and easy to follow set of instructions on how to assemble the Bigfoot when out in the field. We also provide setup assistance to our customers to ensure a fast, efficient, and safe assembly.

Custom Control Options

The Bigfoot Rig Walking System comes standard with our encoded wireless pendant for added security and mobility. Using the pendant, the rig operator can freely move about to achieve optimal visibility during rig movements. The pendant features an emergency stop mechanism that will shut down the HPU motors and valves when activated.

A hard-wired pendant control comes as an optional added feature. Following setup, all of the rig’s movement is controlled through the pendant. Easily control spin and steering modes using adjustable steering linkages. Different travel speeds enable rig position control within a ¼ of an inch.

Custom Designed to Operate in the World’s Harshest Environments

We’ve conducted tireless field testing to prove that the Bigfoot is the world’s safest, most reliable, precision controlled custom rig walking system. From the sub-zero temperatures of northern Alaska to the scorching desert heat of Saudi Arabia, Columbia Industry’s Bigfoot Walking Systems were designed to thrive in the world’s toughest environments.

The design concepts used by Columbia Industries are both customizable and scalable. Contact our team of experts to learn more about how our walking drill rig systems can fit your custom application.

Contact Us Today!

CERTIFICATIONS

OUR LOCATION

5775 NE Wagon Drive

Hillsboro, OR 97124 USA

+1.503.531.0600

+1.503.531.0601 (Fax)

CUSTOMER SUPPORT HOTLINE

Parts & Service

+1.866.531.0600 [email protected]